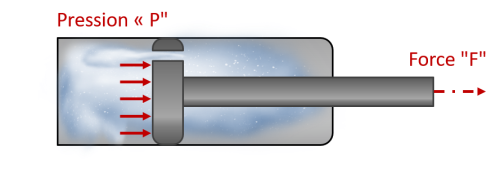

The piston is pushed forward by the gas.

It is designed to set and regulate the speed of the rod exit.

Application example: Lowering, tilting and damping of sashes.

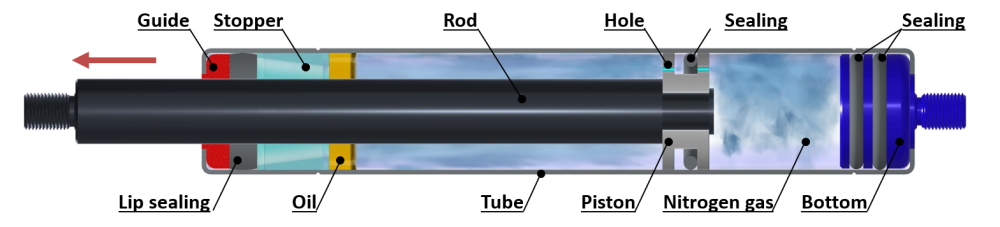

The compression gas spring consists of a cylindrical, watertight body called the Tube and a steel Rod at the end of which is mounted a Piston, which performs cycles of compression and expansion inside the tube. The Tube contains pressurized Nitrogen and a small quantity of Oil.

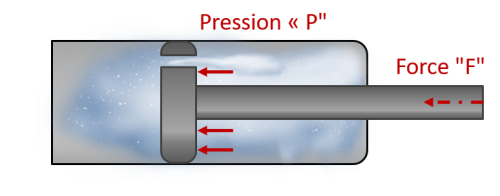

During the compression phase, the Gas flows from the right to the left side of the Piston through the Piston Orifices. At this point, the pressure inside the Tube rises, generating an increase in force.

The flow of Gas can be modulated by adjusting the diameter of the Orifices, in order to regulate the speed at which the Rod leaves the cylinder.

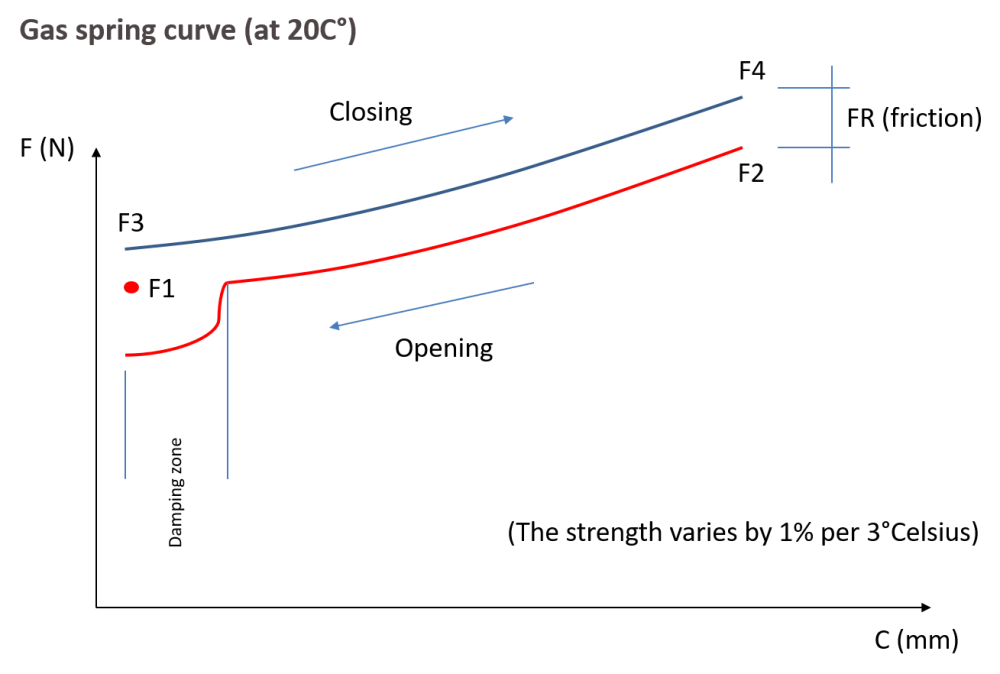

The rate of progression (also known as stiffness) can be modified by acting on the diameters of the Rod/Body pair and on the quantity of Oil (see force diagram below).

|

Determination of a FORCE: Force = Pressure x Surface (DaN) (bars) (cm2 of piston) (1 DaN = 10N) (P Max 160 bars) |

Mariotte’s law: Pressure x Volume = constant (with CONSTANT temperature) P in Pascal (100 000 Pascal = 1 bars) V in M3 |

|

|

| Volume increases therefore pressure and force decreases | Volume decreases therefore pressure and force increases |